MANUFACTURE OF PRECISION COMPONENTS FOR THE AUTOMOBILE INDUSTRY.

Research and

Development

We actively support our customers with product design in the product development phase. To ensure efficient and cost-effective manufacturing, we assess the implementation possibilities and the processing safety for the desired components in advance. During the serial production you continuously receive impulses as part of our continuous improvement process in order to recognise potentials on time.

Quality and

Reliability

Quality is our highest priority and an integral element of our corporate mission statement. “Zero errors” is the ambitious goal that we constantly aim to achieve with each individual product that we produce. We fulfil our technical, economical and deadline agreements in a target-oriented and prompt manner.

KÖNIG Automotive develops specialised, product-specific solutions such as clamping devices, measurement and auxiliary equipment in order to constantly optimise our quality assurance management.

production and warehouse space

employees

components

System Providers

and Logistics

At KÖNIG Automotive, you will receive your components or component assemblies exactly the way you want: Ready-to-install and of the highest quality. You don’t need to take care of anything, we do everything for you.

Polwelle

Sinterteil, Stanzteil und Magnetring, 50.000 Stück/Jahr Highlight: Montage, Bearbeitung der Baugruppe mit Abstandstoleranz ± 0,005 mm, Größe: Ø ca. 38 mm

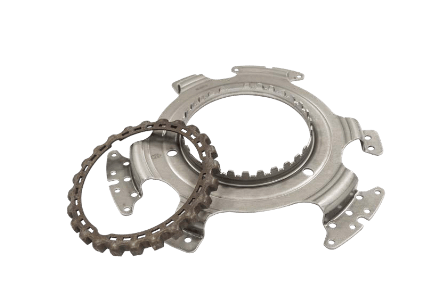

Mitnehmerring

Stanzteil, 624.000 Stück/Jahr

Highlight: Rollierverbindung von zwei Bauteilen, Größe: Ø ca. 265 mm

Turbinennabe

Schmiedeteil, 832.000 Stück/Jahr

Highlight: Beidseitige Bearbeitung inkl. Automation, Größe: Ø ca. 100 mm

Hülse

Nahtloses Rohr, 180.000 Stück/Jahr Highlight: Extrem dünnwandiges Bauteil, Sonderspannmittel, Beschichtung, Größe: Ø ca. 87 mm

Zahnkranz

Ring mit Verzahnung, 30.000 Stück/Jahr Highlight: Herstellen einer H7-Passung, deformations- empfindliches Spannen, Größe: Ø ca. 300 mm

Deckel

Vollmaterial, 3.000 Stück/Jahr Highlight: Spezielle Rillengeometrie, 94 % Zerspanung, Größe: Ø ca. 182 mm

Kolben

Stanzteil, 600.000 Stück/Jahr Highlight: Automatisiertes Hartdrehen, Größe: Ø ca. 150 mm

Gehäuse

Stanzteil geschweißt, 250.000 Stück/Jahr

Highlight: Zentrierung über Hirtverzahnung und Wuchten, Größe: Ø ca. 205 mm

The Environment and

Resources

The responsible treatment of our environment and the conservative use of resources is one of our primary corporate goals. As a company, we do not just set ourselves environment-related goals, we are constantly monitoring the current impact we are having on our environment and the latest statutory regulations. Acting in an environmentally-conscious manner is simply a given for all our employees.

Career at

KÖNIG AUTOMOTIVE

To strengthen our team, we are currently looking for:

> CNC lathe operator (m/f)

> Shift manager for the machining department (m/f)

> Maintenance technician (m/f)

> Machine operator (m/f)

Please send your detailed application by e-mail to: jobs(at)koenig-automotive.de. If we do not have a corresponding opening currently on offer for you, please also feel free to send us an unsolicited application.

or by post to:

König Automotive GmbH Postfach 1434

77767 Appenweier

Apply for Apprenticeship

at KÖNIG!

We know that competent employees make the decisive contribution to the success of our corporate group. And that is why we are especially committed to the education and further development of our skilled specialist staff. At KÖNIG, you will enjoy a collegial working atmosphere, an attractive apprenticeship salary and good promotion opportunities. Start your future career with us as a

> Technical product designer (m/f)

> Industrial mechanic specialising in machining technology (m/f)

> Industrial mechanic specialising in assembly technology (m/f)

> Machine and system operator (m/f)

> Mechatronics engineer (m/f)

> Industrial management assistant (m/f)

Apply here now by e-mail.

Dual Study Programme

With Practical Working Experience

After completing school, would you like to combine your studies with practical working experience? Gain a qualified university degree while also getting valuable practical working experience at the same time. There’s no better way to start a successful career! From the very beginning of the practical working phases, you will get to know the various departments and tasks that make up our company. Get your career started with an exciting time full of personal and knowledge development. We offer the following possibilities:

> Dual study programme in industrial engineering

> Dual study programme in mechanical engineering

> Dual study programme in industrial business studies

If you have any questions in relation to our dual study programmes or our company, please feel free to send us an e-mail. Or apply right here right now by e-mail.